Deeply Rooted in Intelligent Manufacturing, Crafting Cleaning Benchmarks – Unveiling the Strength of PINSIDUN, China's Top Floor Scrubber Factory

Jan 17, 2026

In today's rapidly developing cleaning equipment industry, floor scrubbers have gradually penetrated from industrial settings into diverse fields such as commercial and household use. Behind high-quality products, there must be the support of a strong factory. In the landscape of Chinese floor scrubber manufacturing, PINSIDUN, located in Hefei, Anhui Province, has become a recognized top manufacturing benchmark in the industry, thanks to its solid technological foundation, rigorous quality control system, and comprehensive service capabilities, embodying the core essence of a "great Chinese factory" through craftsmanship and intelligent manufacturing.

Technology as the Core, Building a Solid Foundation for Product Competitiveness

For a floor scrubber factory, core technology is fundamental to its market position. PINSIDUN has always prioritized R&D investment, deeply cultivating innovation in cleaning technology, and forming a technical system that is both practical and forward-looking. Taking its flagship product, the PSD-XS 530B walk-behind floor scrubber, as an example, this equipment, designed specifically for industrial and commercial settings, embodies several of the factory's core technological achievements: equipped with a 24V/500W branded motor and adjustable brush pressure of 30-35kg, it can efficiently remove stubborn stains and adapt to various floor materials such as marble and tiles, achieving a cleaning efficiency of up to 2800㎡/h, easily meeting the cleaning needs of large venues.

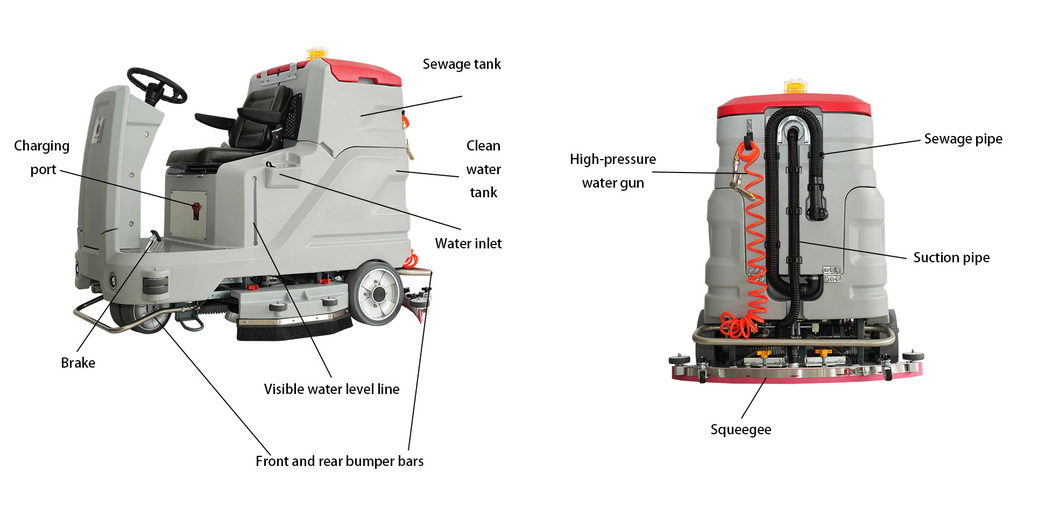

In terms of detailed design, the PINSIDUN factory further demonstrates its deep understanding of user pain points. The equipment uses a cast aluminum squeegee, which is not only aesthetically pleasing but also rust-proof and durable, solving the problem of easy corrosion and short lifespan of traditional floor scrubber water suction components; it is also equipped with a motor overload protection device, extending the motor's service life and reducing equipment failure rates through intelligent control. Addressing noise concerns in cleaning scenarios, the factory optimized the body structure design, controlling equipment noise to ≤70dB, achieving a perfect balance between efficient cleaning and quiet operation, suitable for noise-sensitive environments such as supermarkets, workshops, and offices.

Quality as the Soul, Full-Link Quality Control Protecting Every Piece of Equipment

The confidence of a top factory stems from its ultimate pursuit of quality. The PINSIDUN floor scrubber factory has established a comprehensive quality control system covering the entire process from raw material procurement to finished product delivery, ensuring rigorous standards are applied to every stage of production. For raw materials, the factory selects high-quality ABS environmentally friendly materials for the machine body, combining impact resistance and wear resistance to ensure the equipment remains stable and reliable even under high-intensity use. Core components, such as batteries, are sourced from reputable brands and undergo multiple tests and verifications to guarantee stable performance and safety, preventing quality issues from the source.

In the production process, the PINSIDUN factory has introduced modern production equipment, achieving automated control of mold development, component processing, and complete machine assembly. This not only improves production efficiency but also ensures consistent product precision. Before each floor scrubber leaves the factory, it undergoes multi-dimensional testing covering cleaning effectiveness, battery life, noise level, and safety performance. Only when all indicators meet the standards can the product be shipped. This commitment to quality has earned PINSIDUN floor scrubbers widespread market recognition, and their equipment, known for its durability and stable performance, has become a preferred brand in the industrial cleaning sector.

Service as a Cornerstone: Building a Full-Cycle Guarantee System

A truly top-tier factory not only produces excellent products but also provides excellent service. The PINSIDUN floor scrubber factory understands that as a durable piece of equipment, subsequent technical support and maintenance services directly impact the user experience. Therefore, it has built a comprehensive, full-cycle service guarantee system. Addressing customer needs, the factory provides professional technical support. Whether it's equipment operation guidance, daily maintenance tips, or troubleshooting solutions, the experienced service team responds quickly to resolve customer issues promptly.

To make service more efficient, the PINSIDUN factory has established an online support platform, integrating detailed product documentation and video tutorials for easy access and learning. They also provide remote technical support, using digital tools to quickly identify problems and reduce on-site repair costs and time. For complex malfunctions, the factory can provide on-site service, including maintenance, repair, and parts replacement, ensuring the equipment returns to normal operation as quickly as possible. Furthermore, the factory provides comprehensive warranty services for its entire range of floor scrubbers, covering core components and wear parts, providing tangible guarantees to alleviate customer concerns. Rooted in Industrial Clusters, Leading the Industry's Development

The Chinese floor cleaning machine industry has formed several industrial clusters, with the Anhui region becoming a core hub due to its complete supply chain and strong manufacturing base. PINSIDUN's floor cleaning machine factory is rooted in this region, fully leveraging regional industrial advantages and integrating high-quality supply chain resources to create unique competitive advantages in cost control, component procurement, and technological collaboration. Deep cooperation with upstream and downstream enterprises in the region ensures efficient production and allows for rapid adoption of cutting-edge industry technologies, driving continuous product iteration and upgrades.

In the fierce market competition, PINSIDUN's floor cleaning machine factory consistently adheres to the philosophy of "empowering cleaning with technology and winning trust with quality." Instead of pursuing short-term gains, it focuses on the essence of manufacturing, using every high-quality floor cleaning machine to showcase the intelligent manufacturing capabilities of Chinese factories. From industrial workshops to commercial supermarkets, from large warehouses to public venues, PINSIDUN's equipment is now used in various cleaning scenarios, becoming synonymous with a "reliable floor cleaning machine factory" in the minds of countless customers.

In the future, with the development trend of intelligent and lightweight cleaning equipment, PINSIDUN's floor cleaning machine factory will continue to be driven by technological innovation and supported by quality service, constantly pushing the boundaries of manufacturing to provide global users with more efficient, durable, and intelligent cleaning solutions, continuously leading the Chinese floor cleaning machine manufacturing industry and demonstrating the core strength of Chinese intelligent manufacturing.