How do I choose a ride on floor scrubber?

Dec 06, 2025

How to Choose a Ride-on Floor Scrubber: A Comprehensive Guide

When it comes to maintaining a clean and safe environment in large spaces, a ride-on floor scrubber is an essential piece of equipment. These machines are highly efficient for cleaning large floor areas quickly, but choosing the right one can be overwhelming. With various models, features, and specifications available, it’s important to consider factors such as the type of environment, floor surface, machine capabilities, and budget. In this post, we’ll guide you through the steps to help you choose the perfect ride-on floor scrubber for your needs.

1. Determine Your Cleaning Needs

The first step in selecting a ride-on floor scrubber is to assess your specific cleaning requirements. This includes:

Size of the Area: How large is the space you need to clean? Ride-on scrubbers are ideal for areas ranging from 10,000 to 100,000 square feet, such as warehouses, malls, factories, and schools.

Type of Surface: Different floors (concrete, tile, wood, etc.) require different scrubbing mechanisms. Make sure the scrubber you choose is suitable for the type of floor in your facility.

Level of Dirt and Stains: If the area you’re cleaning has heavy dirt, grease, or industrial residue, you’ll need a machine with stronger scrubbing power and a higher water capacity.

2. Choose the Right Scrubbing Width

The scrubbing width refers to the width of the cleaning path the machine can cover in a single pass. It’s important to choose the right size scrubber for your floor area to ensure optimal efficiency.

Narrow Scrubbing Width (20-30 inches): Best for smaller spaces like retail stores or offices.

Medium Scrubbing Width (30-40 inches): Ideal for medium-sized spaces like schools or hospitals.

Wide Scrubbing Width (40+ inches): Perfect for large industrial areas, warehouses, and factories.

The wider the scrubbing path, the fewer passes the machine will need to make, which saves time.

3. Decide on Battery vs. Propane-Powered Scrubbers

Ride-on floor scrubbers come in two primary power sources: battery-powered and propane-powered.

Battery-Powered Scrubbers: These are the most common choice for indoor use, providing quiet operation with zero emissions. They are also more eco-friendly, though they do require recharging after use.

Propane-Powered Scrubbers: These scrubbers are typically used in larger, outdoor spaces or facilities with excellent ventilation. They provide more power and longer operation times but can be noisy and produce exhaust fumes.

4. Consider the Type of Scrubbing Technology

There are three main types of scrubbing technology used in ride-on floor scrubbers:

Disk Scrubbers: These have rotating circular brushes that clean the floor. They are effective for flat surfaces and provide a consistent clean.

Cylindrical Scrubbers: These use two cylindrical brushes that rotate in opposite directions. They are great for cleaning areas with heavy debris, such as in warehouses, and can collect dirt directly into a hopper.

Orbital Scrubbers: These use an oscillating motion, which makes them effective for more aggressive cleaning and scrubbing uneven surfaces or hard-to-reach areas.

5. Evaluate Water and Solution Capacity

For larger areas, you need a scrubber that can hold enough water and cleaning solution to reduce downtime for refilling. Check the following:

Solution Tank: A larger tank allows the scrubber to clean a bigger area without needing frequent refills.

Recovery Tank: This holds the dirty water the machine collects while cleaning. Larger recovery tanks mean less emptying during cleaning.

Balancing water and solution capacity with the size of your cleaning area can significantly improve productivity.

6. Consider Maneuverability and Size

While ride-on scrubbers are larger than walk-behind models, maneuverability is still a key factor. A machine that’s difficult to maneuver around tight corners or narrow aisles can reduce your efficiency. When evaluating maneuverability:

Look for machines with a tight turning radius for better control.

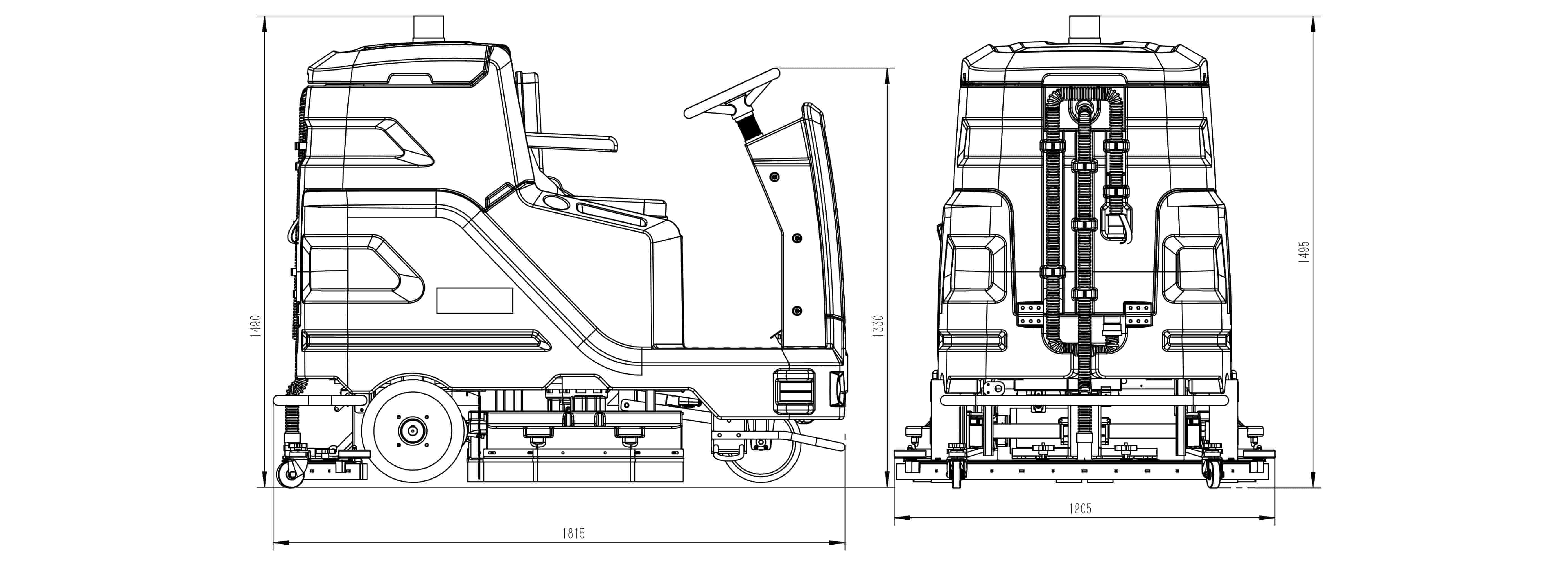

Consider the machine’s overall size to ensure it can navigate through doorways and hallways.

7. Maintenance and Cost of Ownership

Like any piece of equipment, a ride-on floor scrubber requires maintenance. Consider the following:

Ease of Maintenance: Does the scrubber have easily accessible parts? Can you clean and replace brushes, squeegees, and batteries without a lot of hassle?

Spare Parts Availability: Ensure that parts are readily available and easy to replace, minimizing downtime.

Warranty: A good warranty can help cover unexpected repair costs. Be sure to check the warranty terms before purchasing.

8. Budget Considerations

Finally, while it’s tempting to opt for the cheapest model, the price should reflect the features and performance you need. Keep in mind that:

Upfront Cost: Ride-on floor scrubbers can range from a few thousand dollars to tens of thousands depending on the features, size, and brand.

Long-Term Costs: Consider ongoing expenses such as electricity, battery replacement, parts, and maintenance.

9. Review Customer Feedback and Manufacturer Reputation

Before making your final decision, take the time to read customer reviews and gather insights on the reputation of the manufacturer. This can give you a better idea of the scrubber’s durability, ease of use, and long-term reliability.

Conclusion

Choosing the right ride-on floor scrubber is crucial for maintaining clean and safe environments, especially in large spaces. By evaluating your cleaning needs, the type of surface you’ll be working on, power options, scrubbing technology, and other factors, you can find a machine that balances performance, cost, and efficiency. Keep in mind that investing in a high-quality scrubber will ultimately save you time and money, as well as ensure cleaner floors in your facility.

For more information or to browse a variety of ride-on floor scrubbers, visit our https://www.pinstonclean.com and get expert advice on choosing the best model for your needs.