Learn about Pinston floor scrubbers in one article: structural principles, core modules and selection recommendations

Jul 10, 2025

In past tweets, we have talked about the application advantages of floor scrubbers in commercial and industrial scenarios, including improving cleaning efficiency, reducing labor costs, and promoting standardization of cleaning management. However, truly understanding the working logic and technical points of floor scrubbers will help users choose and use equipment more scientifically and give full play to the performance advantages that the equipment should have.

Today, we will give you a comprehensive understanding of the structural principles, key components and usage recommendations of the Pinston floor scrubber to help you better understand the technical logic behind a "good machine".

After reading this article, you will gain:

1. Brief analysis of the internal structure and core modules of the floor scrubber

2. Selection suggestions for different operating scenarios

3. How to judge the "efficiency and durability" of a floor scrubber

4. Pinston’s design ideas and usage tips

The basic structure and working principle of floor scrubber

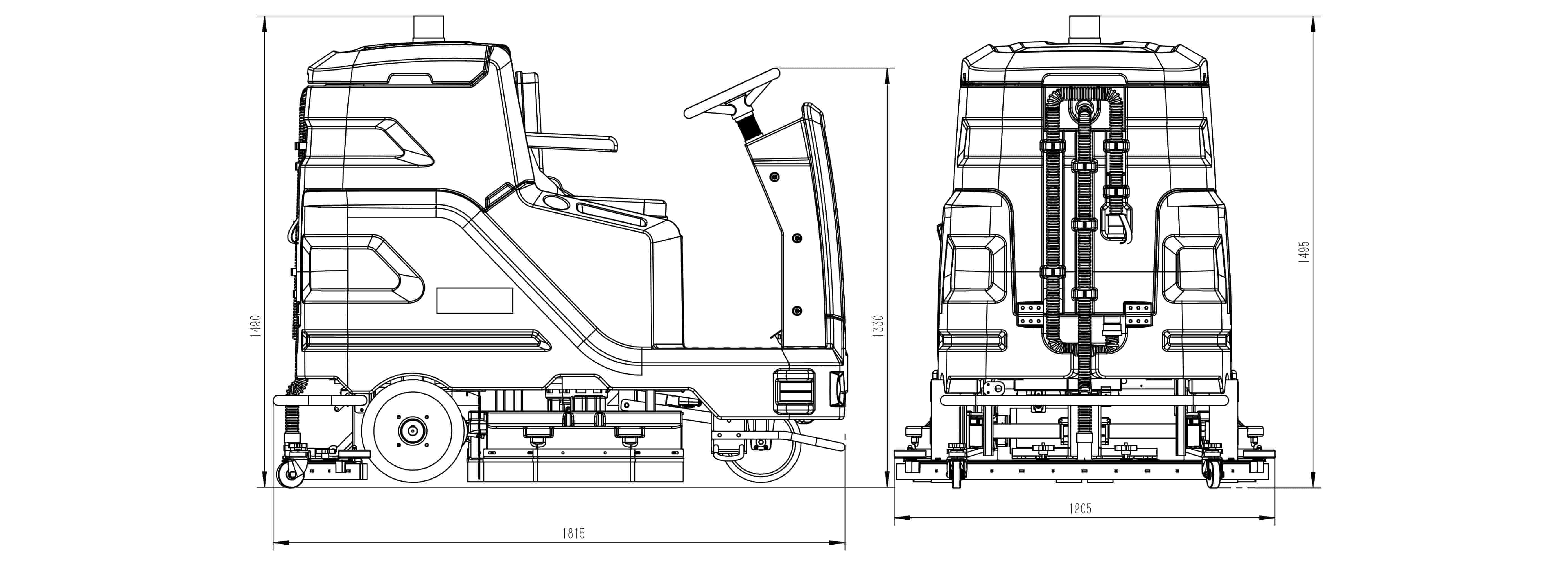

Whether it is a push-type or ride-on floor scrubber, the core working principle is roughly the same - the cleaning action is completed through the three closed loops of clean water system + scrubbing system + sewage recovery system .

1. Clean water system

It includes clean water tank, water pump, water pipe and other modules. When the equipment is running, the water pump delivers clean water to the brush plate area to moisten and soften the dirt. Pinston equipment is generally equipped with a pressurized water system to ensure uniform water output and stable flow, which helps to improve the cleaning coverage.

2. Scrubbing system

Including motor drive, brush plate assembly, and pressure system. Different models can be equipped with brushes of different materials (nylon, PP, abrasive brushes) or floor mats (red mat, black mat, diamond mat, etc.). Most models of Pinston support automatic lifting and floating floor design of brush plates to improve ground fit and cope with different floor height differences.

3. Wastewater recycling system

It includes a water suction motor, a water suction squeegee, a sewage tank, etc. The water suction squeegee is close to the ground to collect the dirty water after scrubbing, and is pumped into the sewage tank through the water suction motor. Pinston uses a high-performance air-cooled motor + multiple filtering structure to prevent dust or foam from entering the motor cavity and increase the life of the motor.

How to choose the model for different scenarios?

It is critical to choose the right equipment model according to the usage scenario and cleaning intensity. The following are common environments and recommended ideas .

How to judge whether the floor scrubber is "worth buying"?

When selecting equipment, in addition to brand and price, you should also pay attention to the following key technical indicators:

Brush pressure and brush motor power : Determine cleaning performance

Battery capacity and battery life : Determine continuous working ability

Air volume and vacuum degree of water suction motor : determine whether the ground is dry and free of residue

Whether the whole machine structure is easy to maintain : determines the long-term use cost

Pinston has a stable and mature technical route in these performance indicators. Many products have passed the IPX4 waterproof level certification to ensure that the equipment can still operate stably in a humid environment. At the same time, some models are equipped with an LCD display control panel , which can view the brush pressure, power, and water level status in real time, making it convenient for managers to grasp the equipment operation status and cleaning progress.

Usage tips and maintenance suggestions

Daily maintenance:

After the operation is completed, empty the clean water tank and the sewage tank in time

Clean the filter basket to prevent debris from clogging the system

Check the brush and squeegee for wear and replace if necessary

Periodic maintenance:

battery voltage and electrolyte weekly (applicable to lead-acid batteries)

the motor ventilation holes monthly to prevent dust from clogging and causing overheating

Regularly replace the absorbent strips, brushes and other consumable parts to ensure the cleaning effect

Note:

Avoid dry brushing to avoid damaging the floor and brush plate

Do not leave the device in high temperature or high humidity environment for a long time

Do not use corrosive chemicals to avoid damaging the pump body and rubber strips.

Conclusion

Pinston floor scrubber is not only a cleaning tool, but also an " efficiency amplifier " for modern cleaning management. Through its intelligent and humanized design concept, users can significantly improve cleaning efficiency, reduce operation and maintenance costs, and enhance on-site image.

Whether you are a property management company, a cleaning service outsourcing company , or a corporate logistics department that needs to operate its own cleaning , choosing a suitable Pinston floor scrubber can achieve twice the result with half the effort and a cleaning efficiency of 1+1>2.